Benchtop Guide

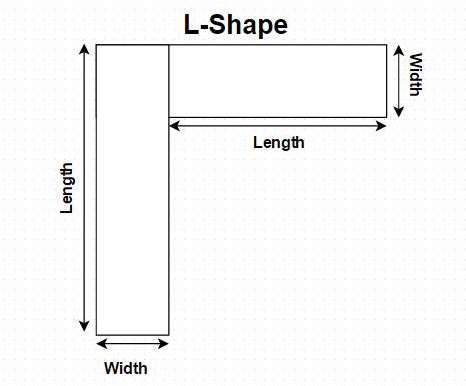

DESIGN: One very important step is to ensure you create a good basic diagram of your kitchen.

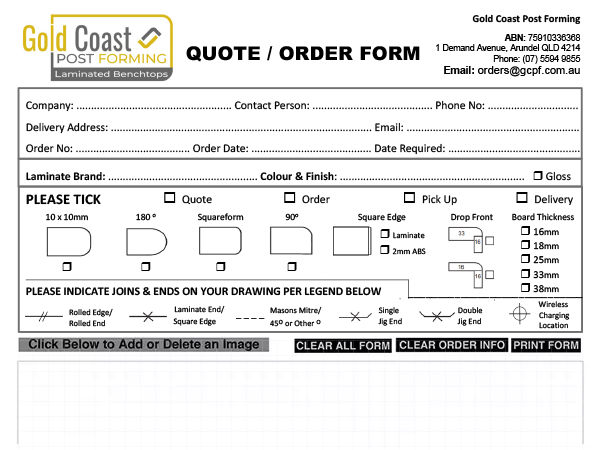

If you’re not comfortable with home renovations or taking accurate measurements, then we strongly recommend you get in touch with someone who is, like a skilled local cabinet maker. However, if you have a fairly simple design and/or you are confident with taking accurate measurements, then please download our order form. Follow this guide to help with the quoting/ordering process.

LAMINATE: Choosing a laminate that you love and will suit your style is probably a good start.

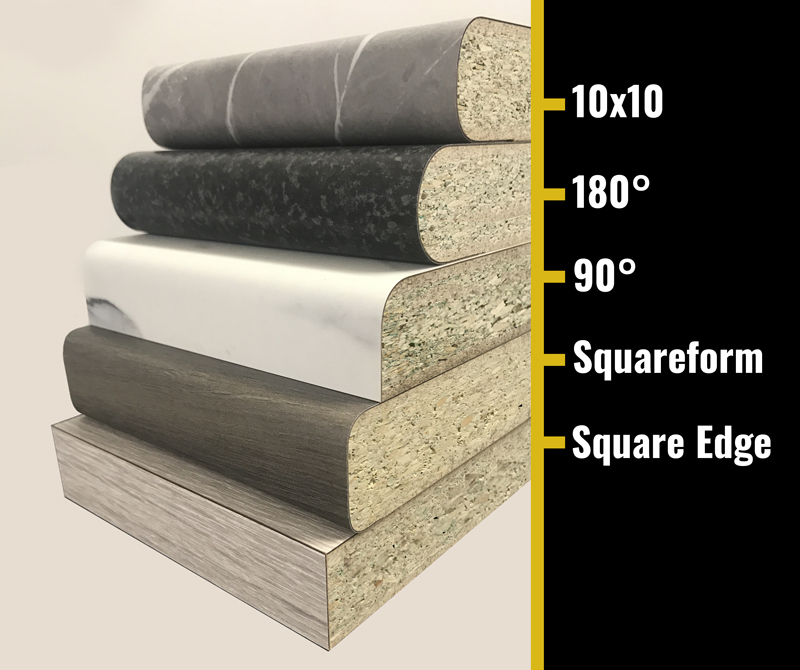

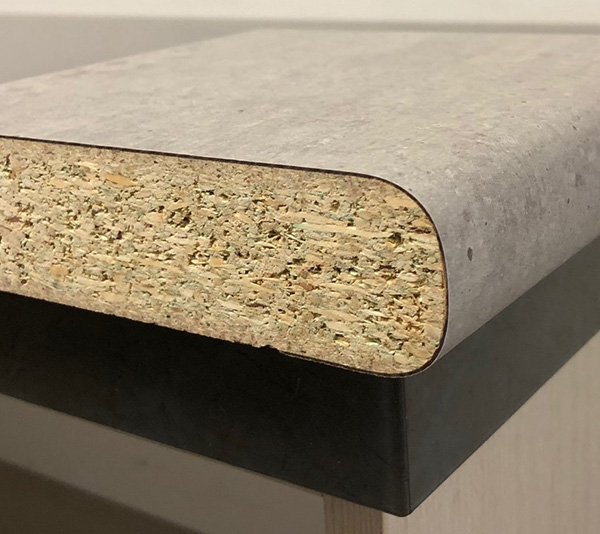

PROFILE: It is also important to decide on the benchtop profile finish.

POPULAR PROFILES

10x10

The most common profile. Not only does it look good, but almost any laminate can be formed to a 10mm radius postformed / rolled edge.

180°

Also known as bull nose. This is more rounded than the 10×10 profile. It is a practical and conventional postformed / rolled edge.

90°

Although not very common anymore 90° is still used for for drop fronts / vanities and aprons.

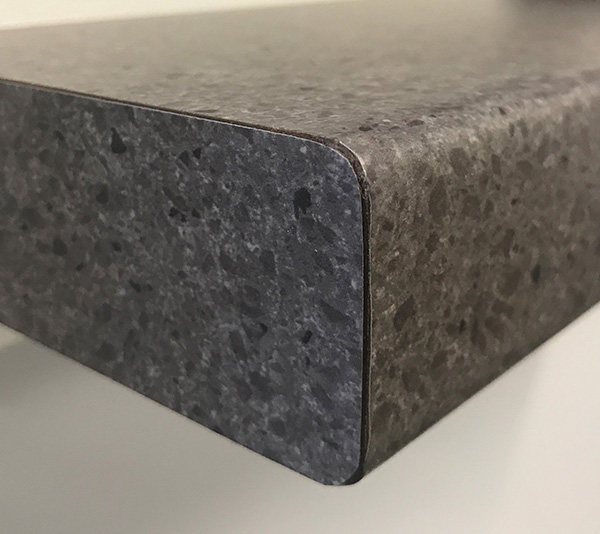

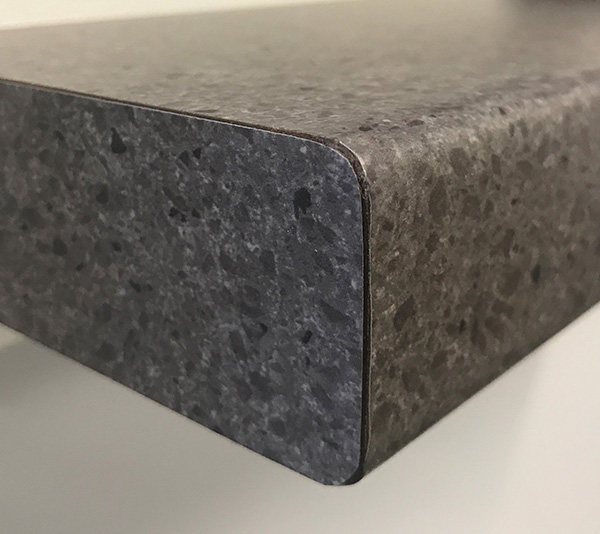

Squareform®/Tightform/5x5

Laminate Square Edge

ABS Edge

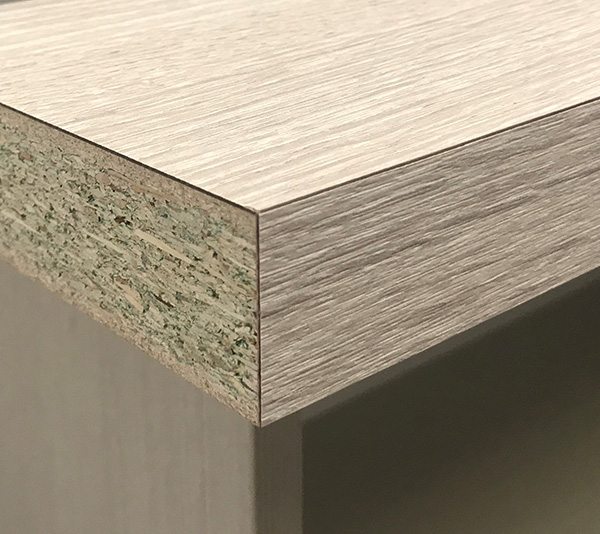

THICKNESS: You will also need to think about the preferred thickness* of your tops.

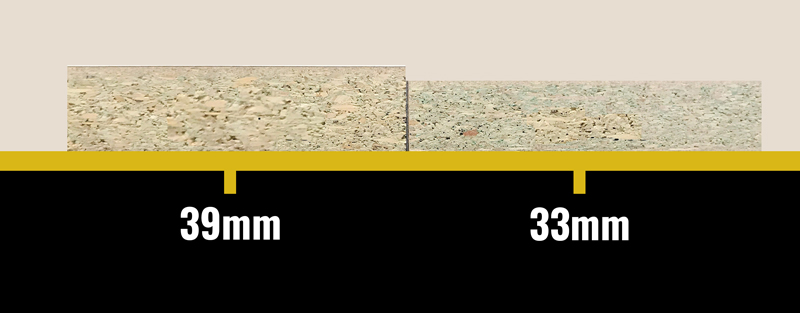

If you are replacing existing tops you should consider having the new tops made to the same thickness especially if you are trying to avoid replacing any splash backs or tiling. Our standard thickness options are 33mm or 39mm.

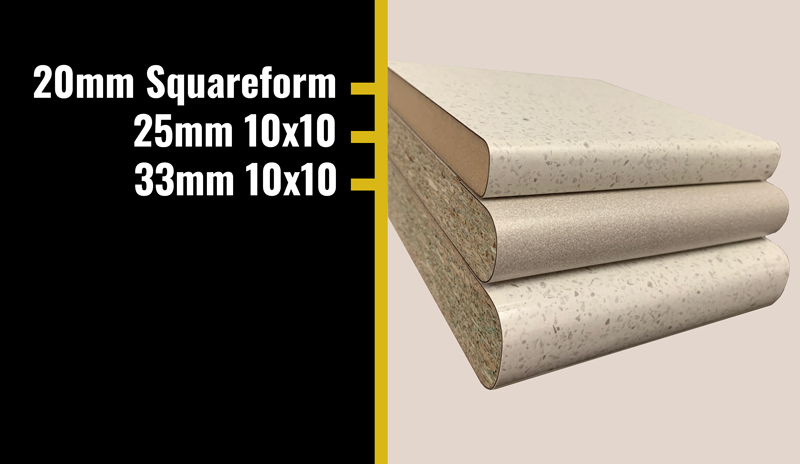

We also offer non-standard thicknesses. For example we can Squareform® a 20mm profile benchtop, which (with the right laminate choice) can closely mimic a modern thinner stone finish at a fraction of the cost. The photo also shows a 25mm 10×10 profile and how these non-standard thicknesses compare with a standard 33mm 10×10 benchtop.

*Please note there can be a slight variation of approximately 1mm in the finished product thickness due to board or laminate manufacturing variations.

CORNERS: The corner finish is a further consideration.

CORNER OPTIONS

Laminated End

Jig End

Frogs Eye

Mini-Form

DROP FRONTS: This is an option that can also be fabricated.

WATERFALL ENDS: Create a continuous benchtop that ‘waterfalls’ to the ground.

FINALISING ORDER: Now you’ve reviewed the ordering guide and other reference material you might be ready to get a quote or place an order.